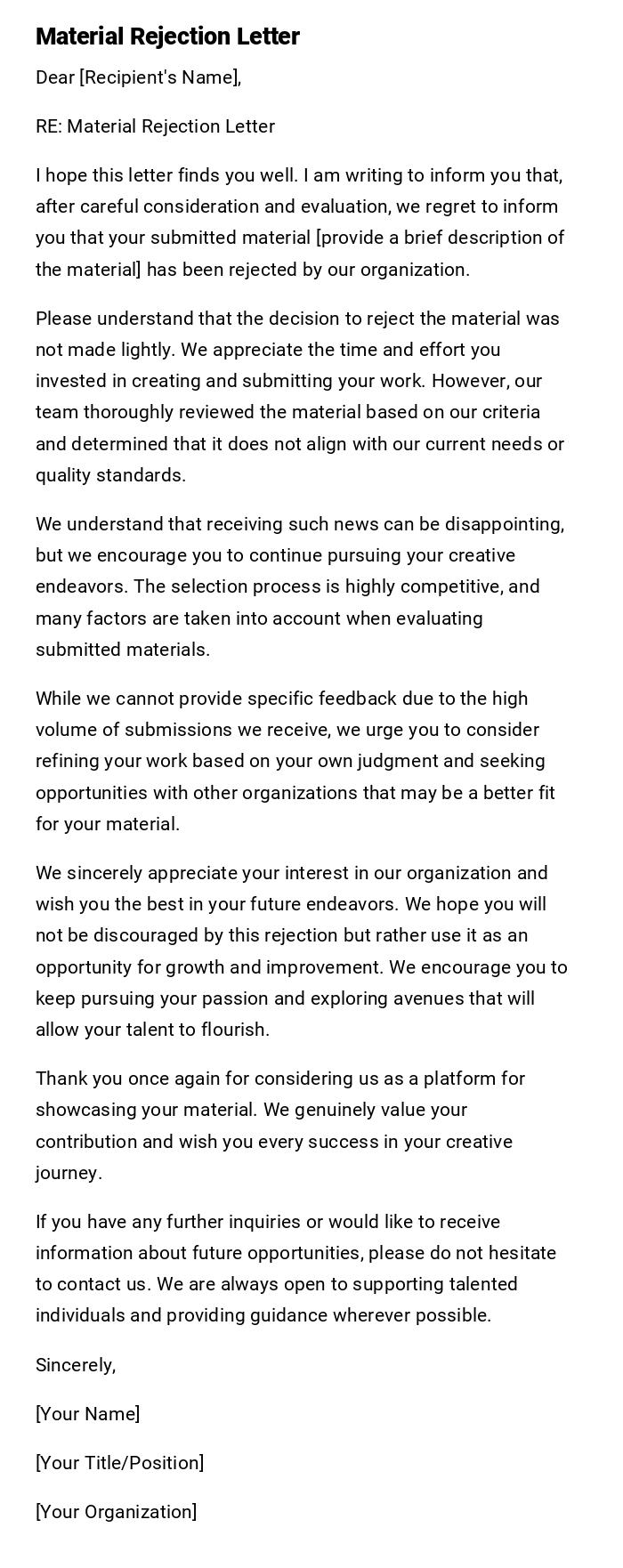

Material Rejection Letter

Dear [Recipient's Name],

RE: Material Rejection Letter

I hope this letter finds you well. I am writing to inform you that, after careful consideration and evaluation, we regret to inform you that your submitted material [provide a brief description of the material] has been rejected by our organization.

Please understand that the decision to reject the material was not made lightly. We appreciate the time and effort you invested in creating and submitting your work. However, our team thoroughly reviewed the material based on our criteria and determined that it does not align with our current needs or quality standards.

We understand that receiving such news can be disappointing, but we encourage you to continue pursuing your creative endeavors. The selection process is highly competitive, and many factors are taken into account when evaluating submitted materials.

While we cannot provide specific feedback due to the high volume of submissions we receive, we urge you to consider refining your work based on your own judgment and seeking opportunities with other organizations that may be a better fit for your material.

We sincerely appreciate your interest in our organization and wish you the best in your future endeavors. We hope you will not be discouraged by this rejection but rather use it as an opportunity for growth and improvement. We encourage you to keep pursuing your passion and exploring avenues that will allow your talent to flourish.

Thank you once again for considering us as a platform for showcasing your material. We genuinely value your contribution and wish you every success in your creative journey.

If you have any further inquiries or would like to receive information about future opportunities, please do not hesitate to contact us. We are always open to supporting talented individuals and providing guidance wherever possible.

Sincerely,

[Your Name]

[Your Title/Position]

[Your Organization]

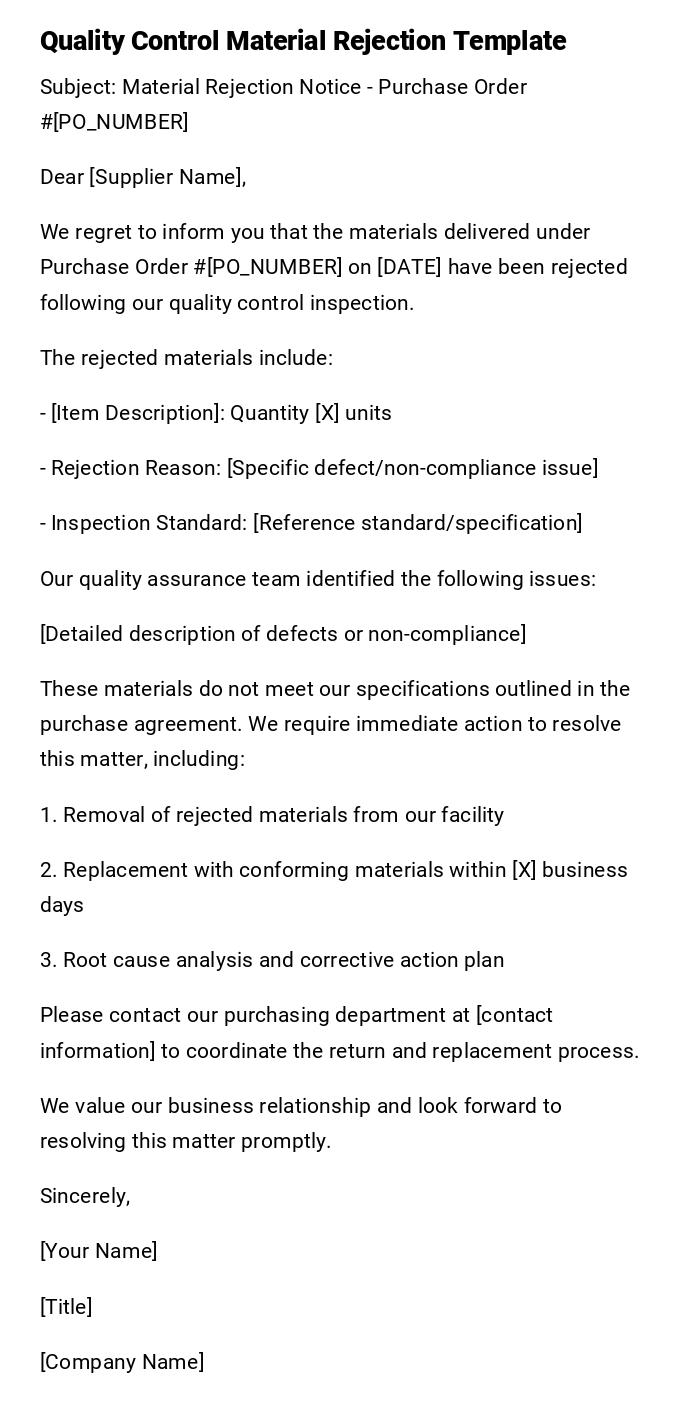

Quality Control Material Rejection - Professional

Subject: Material Rejection Notice - Purchase Order #[PO_NUMBER]

Dear [Supplier Name],

We regret to inform you that the materials delivered under Purchase Order #[PO_NUMBER] on [DATE] have been rejected following our quality control inspection.

The rejected materials include:

- [Item Description]: Quantity [X] units

- Rejection Reason: [Specific defect/non-compliance issue]

- Inspection Standard: [Reference standard/specification]

Our quality assurance team identified the following issues:

[Detailed description of defects or non-compliance]

These materials do not meet our specifications outlined in the purchase agreement. We require immediate action to resolve this matter, including:

1. Removal of rejected materials from our facility

2. Replacement with conforming materials within [X] business days

3. Root cause analysis and corrective action plan

Please contact our purchasing department at [contact information] to coordinate the return and replacement process.

We value our business relationship and look forward to resolving this matter promptly.

Sincerely,

[Your Name]

[Title]

[Company Name]

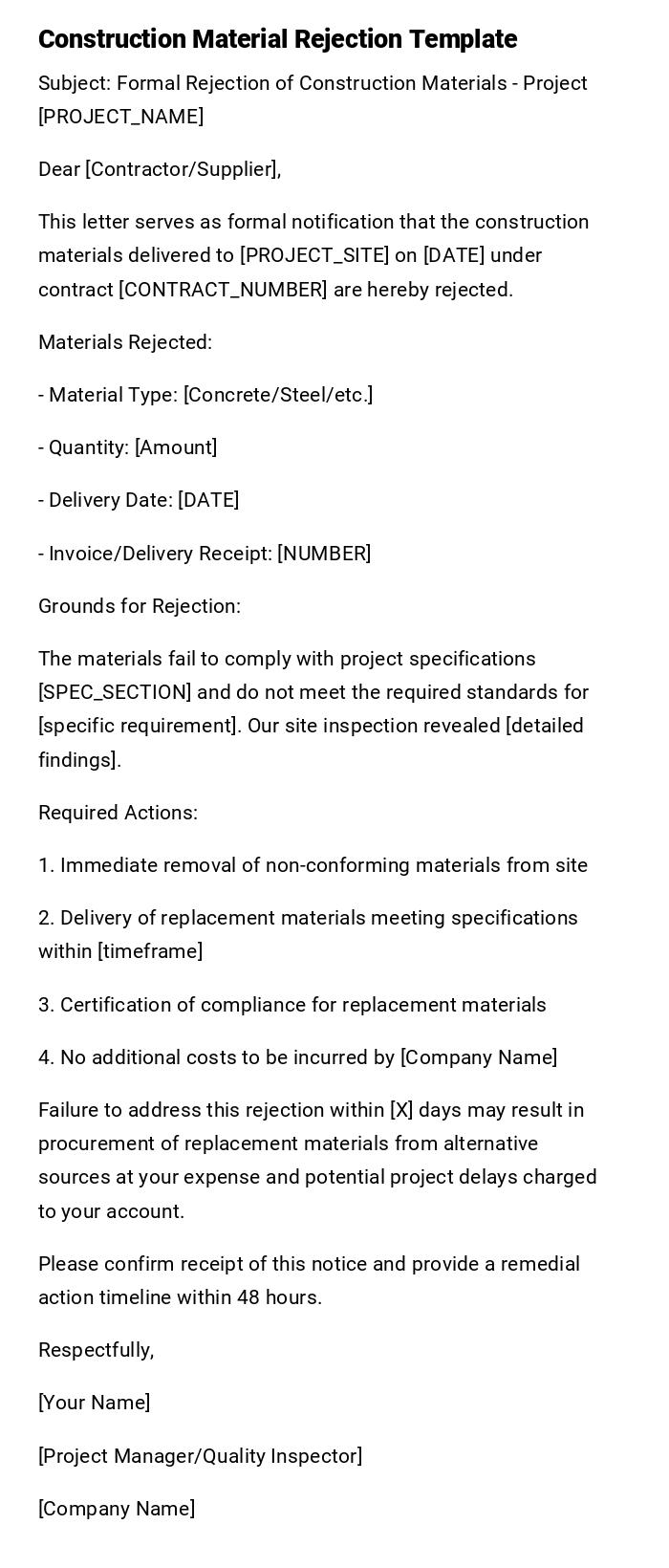

Construction Material Rejection - Formal

Subject: Formal Rejection of Construction Materials - Project [PROJECT_NAME]

Dear [Contractor/Supplier],

This letter serves as formal notification that the construction materials delivered to [PROJECT_SITE] on [DATE] under contract [CONTRACT_NUMBER] are hereby rejected.

Materials Rejected:

- Material Type: [Concrete/Steel/etc.]

- Quantity: [Amount]

- Delivery Date: [DATE]

- Invoice/Delivery Receipt: [NUMBER]

Grounds for Rejection:

The materials fail to comply with project specifications [SPEC_SECTION] and do not meet the required standards for [specific requirement]. Our site inspection revealed [detailed findings].

Required Actions:

1. Immediate removal of non-conforming materials from site

2. Delivery of replacement materials meeting specifications within [timeframe]

3. Certification of compliance for replacement materials

4. No additional costs to be incurred by [Company Name]

Failure to address this rejection within [X] days may result in procurement of replacement materials from alternative sources at your expense and potential project delays charged to your account.

Please confirm receipt of this notice and provide a remedial action timeline within 48 hours.

Respectfully,

[Your Name]

[Project Manager/Quality Inspector]

[Company Name]

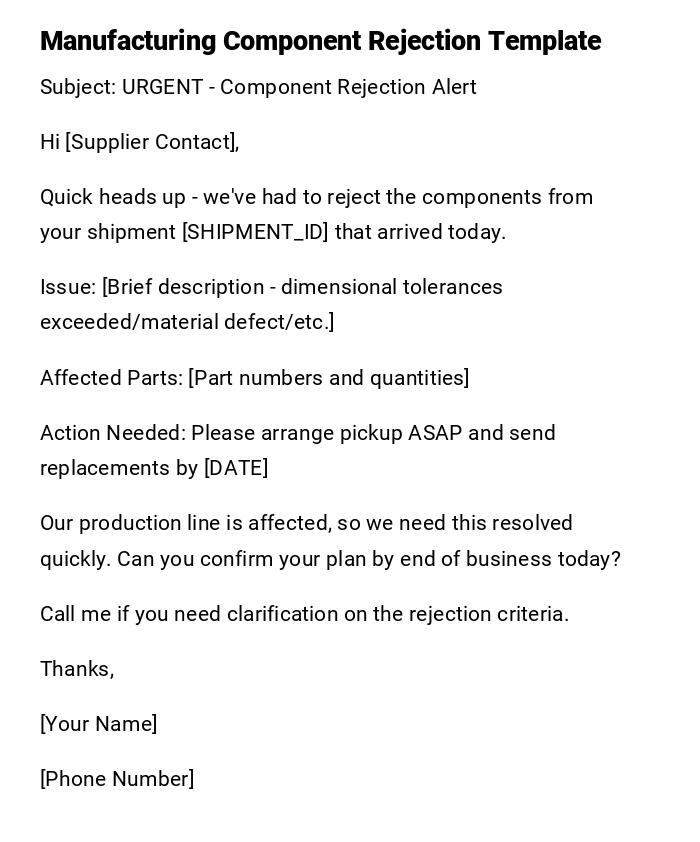

Manufacturing Component Rejection - Quick

Subject: URGENT - Component Rejection Alert

Hi [Supplier Contact],

Quick heads up - we've had to reject the components from your shipment [SHIPMENT_ID] that arrived today.

Issue: [Brief description - dimensional tolerances exceeded/material defect/etc.]

Affected Parts: [Part numbers and quantities]

Action Needed: Please arrange pickup ASAP and send replacements by [DATE]

Our production line is affected, so we need this resolved quickly. Can you confirm your plan by end of business today?

Call me if you need clarification on the rejection criteria.

Thanks,

[Your Name]

[Phone Number]

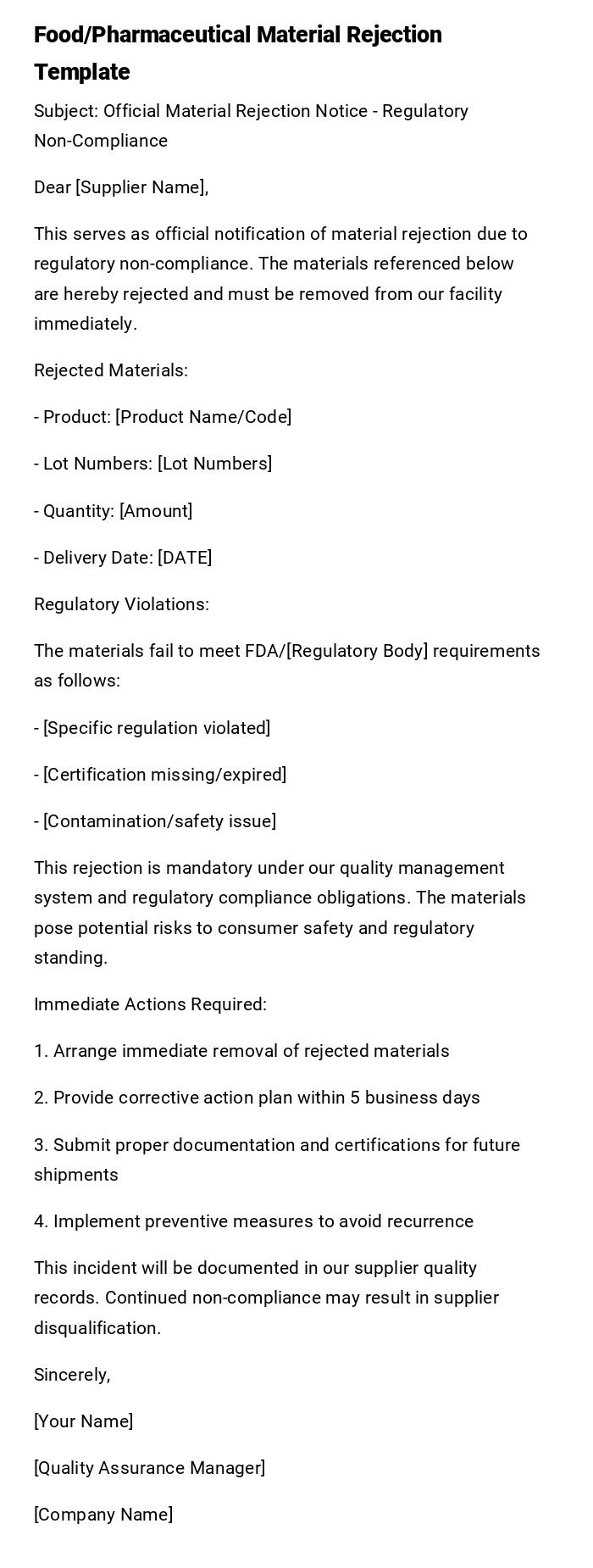

Food/Pharmaceutical Material Rejection - Official

Subject: Official Material Rejection Notice - Regulatory Non-Compliance

Dear [Supplier Name],

This serves as official notification of material rejection due to regulatory non-compliance. The materials referenced below are hereby rejected and must be removed from our facility immediately.

Rejected Materials:

- Product: [Product Name/Code]

- Lot Numbers: [Lot Numbers]

- Quantity: [Amount]

- Delivery Date: [DATE]

Regulatory Violations:

The materials fail to meet FDA/[Regulatory Body] requirements as follows:

- [Specific regulation violated]

- [Certification missing/expired]

- [Contamination/safety issue]

This rejection is mandatory under our quality management system and regulatory compliance obligations. The materials pose potential risks to consumer safety and regulatory standing.

Immediate Actions Required:

1. Arrange immediate removal of rejected materials

2. Provide corrective action plan within 5 business days

3. Submit proper documentation and certifications for future shipments

4. Implement preventive measures to avoid recurrence

This incident will be documented in our supplier quality records. Continued non-compliance may result in supplier disqualification.

Sincerely,

[Your Name]

[Quality Assurance Manager]

[Company Name]

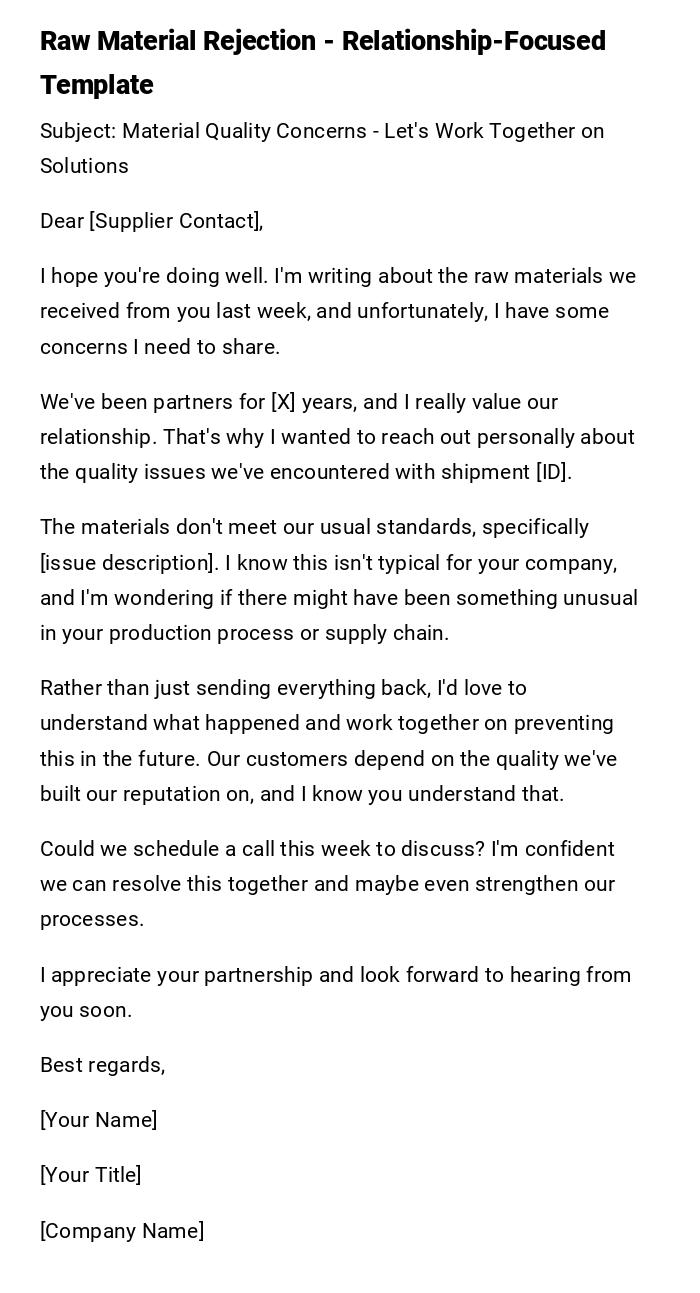

Raw Material Rejection - Heartfelt

Subject: Material Quality Concerns - Let's Work Together on Solutions

Dear [Supplier Contact],

I hope you're doing well. I'm writing about the raw materials we received from you last week, and unfortunately, I have some concerns I need to share.

We've been partners for [X] years, and I really value our relationship. That's why I wanted to reach out personally about the quality issues we've encountered with shipment [ID].

The materials don't meet our usual standards, specifically [issue description]. I know this isn't typical for your company, and I'm wondering if there might have been something unusual in your production process or supply chain.

Rather than just sending everything back, I'd love to understand what happened and work together on preventing this in the future. Our customers depend on the quality we've built our reputation on, and I know you understand that.

Could we schedule a call this week to discuss? I'm confident we can resolve this together and maybe even strengthen our processes.

I appreciate your partnership and look forward to hearing from you soon.

Best regards,

[Your Name]

[Your Title]

[Company Name]

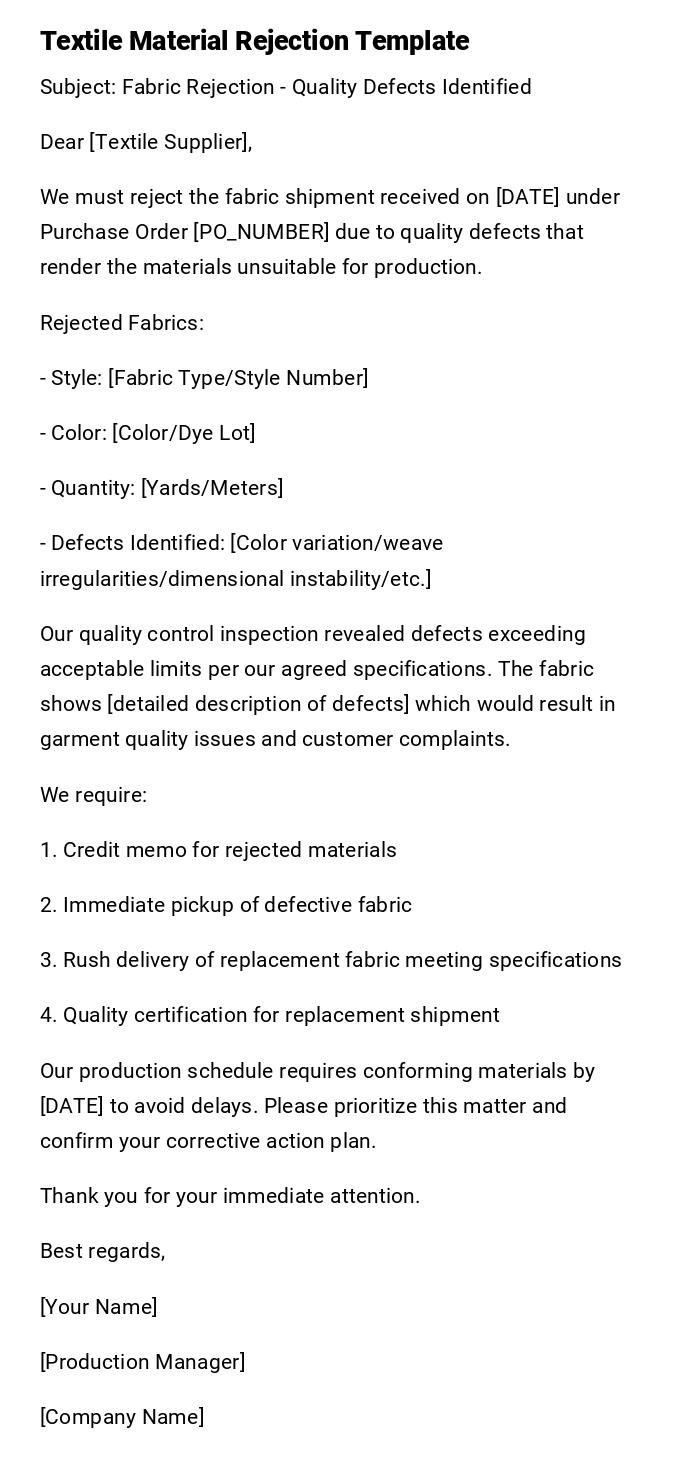

Textile Material Rejection - Professional

Subject: Fabric Rejection - Quality Defects Identified

Dear [Textile Supplier],

We must reject the fabric shipment received on [DATE] under Purchase Order [PO_NUMBER] due to quality defects that render the materials unsuitable for production.

Rejected Fabrics:

- Style: [Fabric Type/Style Number]

- Color: [Color/Dye Lot]

- Quantity: [Yards/Meters]

- Defects Identified: [Color variation/weave irregularities/dimensional instability/etc.]

Our quality control inspection revealed defects exceeding acceptable limits per our agreed specifications. The fabric shows [detailed description of defects] which would result in garment quality issues and customer complaints.

We require:

1. Credit memo for rejected materials

2. Immediate pickup of defective fabric

3. Rush delivery of replacement fabric meeting specifications

4. Quality certification for replacement shipment

Our production schedule requires conforming materials by [DATE] to avoid delays. Please prioritize this matter and confirm your corrective action plan.

Thank you for your immediate attention.

Best regards,

[Your Name]

[Production Manager]

[Company Name]

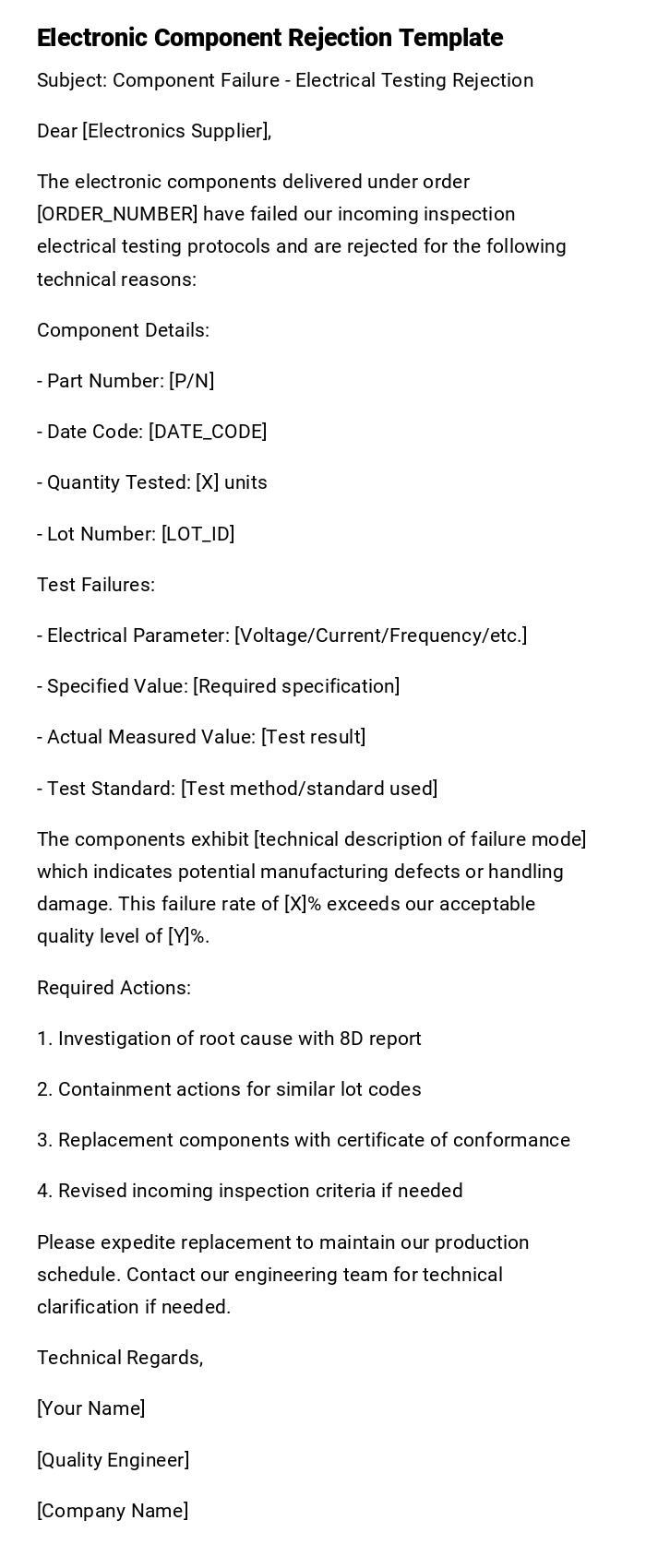

Electronic Component Rejection - Technical

Subject: Component Failure - Electrical Testing Rejection

Dear [Electronics Supplier],

The electronic components delivered under order [ORDER_NUMBER] have failed our incoming inspection electrical testing protocols and are rejected for the following technical reasons:

Component Details:

- Part Number: [P/N]

- Date Code: [DATE_CODE]

- Quantity Tested: [X] units

- Lot Number: [LOT_ID]

Test Failures:

- Electrical Parameter: [Voltage/Current/Frequency/etc.]

- Specified Value: [Required specification]

- Actual Measured Value: [Test result]

- Test Standard: [Test method/standard used]

The components exhibit [technical description of failure mode] which indicates potential manufacturing defects or handling damage. This failure rate of [X]% exceeds our acceptable quality level of [Y]%.

Required Actions:

1. Investigation of root cause with 8D report

2. Containment actions for similar lot codes

3. Replacement components with certificate of conformance

4. Revised incoming inspection criteria if needed

Please expedite replacement to maintain our production schedule. Contact our engineering team for technical clarification if needed.

Technical Regards,

[Your Name]

[Quality Engineer]

[Company Name]

Packaging Material Rejection - Casual

Subject: Packaging Issue - Need Quick Fix

Hey [Supplier Name],

Hope you're well! We've got a bit of a situation with the packaging materials you sent over on [DATE]. Unfortunately, we can't use them and need to get this sorted out.

What's wrong: [Specific issue - wrong size/damaged/print quality/etc.]

What we received: [Description and quantity]

What we actually need: [Correct specifications]

I know these things happen sometimes. Could you please pick up the incorrect materials and get us the right ones by [DATE]? Our packaging line is scheduled to run next week, so timing is pretty important.

Let me know when you can swing by to collect the rejected items, and when we can expect the replacement delivery.

Thanks for taking care of this quickly!

Cheers,

[Your Name]

[Operations Team]

[Phone/Email]

What is a Material Rejection Letter and Why is it Necessary

A material rejection letter is a formal communication document used to officially notify suppliers or vendors that delivered materials, components, or products do not meet specified quality standards, contractual requirements, or regulatory compliance measures. This letter serves multiple critical purposes: it provides legal documentation of non-conformance, initiates the return and replacement process, maintains quality control standards, and preserves business relationships through professional communication. The letter establishes a paper trail for quality management systems, protects against liability issues, and ensures accountability in supply chain operations.

Who Should Send Material Rejection Letters

- Quality Control Managers and Inspectors responsible for incoming material verification

- Purchasing Managers who oversee supplier relationships and contract compliance

- Production Managers when materials affect manufacturing processes

- Project Managers in construction or engineering projects

- Receiving Department Supervisors who first identify material discrepancies

- Compliance Officers in regulated industries (pharmaceutical, food, aerospace)

- Plant Managers or Operations Directors for significant quality issues

- Engineering Teams when technical specifications are not met

- Warehouse Managers for damaged or incorrectly packaged materials

When to Send Material Rejection Letters

- Upon discovery of materials that fail quality control inspection

- When delivered quantities don't match purchase order specifications

- If materials arrive damaged due to poor packaging or shipping

- When certifications or documentation are missing or inadequate

- If materials fail regulatory compliance requirements (FDA, ISO, etc.)

- When dimensional tolerances or specifications are exceeded

- If materials show signs of contamination or environmental damage

- When wrong materials are delivered (different grade, color, model)

- If shelf life or expiration dates are unacceptable

- When materials fail electrical, mechanical, or performance testing

- If packaging doesn't meet handling or storage requirements

How to Write and Send Material Rejection Letters

Start with clear identification of the rejected materials including purchase order numbers, delivery dates, quantities, and specific item descriptions. Document the exact reasons for rejection with reference to applicable standards, specifications, or contract requirements. Include photographic evidence when possible and reference any test data or inspection reports. Clearly state required corrective actions including material removal, replacement timelines, and documentation needs. Maintain a professional tone while being firm about requirements. Send via email for speed with follow-up hard copy when required. Copy relevant internal departments and maintain detailed records for quality management system documentation.

Requirements and Prerequisites Before Sending

- Complete incoming inspection or testing of materials

- Documentation of defects with photos, measurements, or test data

- Review of purchase order specifications and contractual requirements

- Verification of rejection criteria against established quality standards

- Confirmation of proper handling and storage after delivery

- Internal approval from quality manager or authorized personnel

- Preparation of rejection tags or labels for physical materials

- Coordination with receiving and warehouse teams for material segregation

- Review of supplier agreement terms regarding returns and replacements

- Availability of alternative supply sources if needed for production continuity

Formatting Guidelines and Best Practices

Keep letters concise but comprehensive, typically 1-2 pages maximum. Use professional business letter format with clear subject lines for email delivery. Include specific details but avoid overly technical jargon unless writing to technical personnel. Attach supporting documentation such as inspection reports, photos, or test data. Use bullet points for clarity when listing multiple items or issues. Maintain consistent terminology matching purchase orders and specifications. Include all relevant reference numbers for easy tracking. Set clear deadlines for responses and corrective actions. Use firm but respectful language that preserves business relationships while ensuring compliance.

Follow-up Actions After Sending

- Confirm receipt of rejection notice within 24-48 hours

- Track supplier response and corrective action timeline

- Coordinate material pickup with shipping/receiving departments

- Monitor delivery of replacement materials and conduct re-inspection

- Document all communications and actions in quality management system

- Update supplier performance records and scorecards

- Review and update specifications if rejection revealed unclear requirements

- Conduct root cause analysis meeting with supplier if needed

- Implement preventive measures to avoid similar future issues

- Consider supplier audit or qualification review for repeated rejections

- Escalate to management for significant quality or delivery impacts

Common Mistakes and Pitfalls to Avoid

- Failing to document rejection reasons with specific evidence

- Using emotional or accusatory language that damages supplier relationships

- Not providing clear timelines for corrective actions

- Omitting essential reference numbers or identification information

- Sending rejections without proper internal approvals

- Not coordinating with internal teams for material handling

- Failing to follow up on supplier responses and commitments

- Not maintaining proper records for quality system compliance

- Accepting verbal promises without written confirmation

- Delaying rejection notices which complicates return processes

- Not considering the impact on production schedules when setting deadlines

- Missing opportunities to provide constructive feedback for improvement

Essential Elements and Structure

Every material rejection letter must include: clear subject line identifying the rejection, supplier contact information, purchase order or contract references, detailed description of rejected materials with quantities and dates, specific reasons for rejection with supporting evidence, required corrective actions with timelines, contact information for coordination, professional closing with authorized signature. Supporting attachments should include inspection reports, photographs of defects, test data, and copies of relevant specifications. The structure should flow logically from identification through problem description to required solutions, maintaining clarity and professional tone throughout.

Download Word Doc

Download Word Doc

Download PDF

Download PDF